RocketSTEM –28 November 2018

space was unveiled at a welcoming ceremony held at NASA’s Kennedy Space Center (KSC)

in Florida – where it is now being processed for the 1st integrated

test flight launch to the Moon atop the mammoth Space Launch System (SLS)

megarocket on the Exploration Mission-1 (EM-1) in 2020.

NASA

hosted the welcoming event for this first European Service Module – dubbed

ESM-1 – inside the cavernous Neil Armstrong

Operations and Checkout building at KSC on Nov. 16 – and attended by a big crowd of dignitaries from NASA, the

European Space Agency (ESA) who funded its development, the main European and

US industrial contractors and the news media including Space UpClose.

“We will not go back to the moon … We will go forward to the

moon,” said

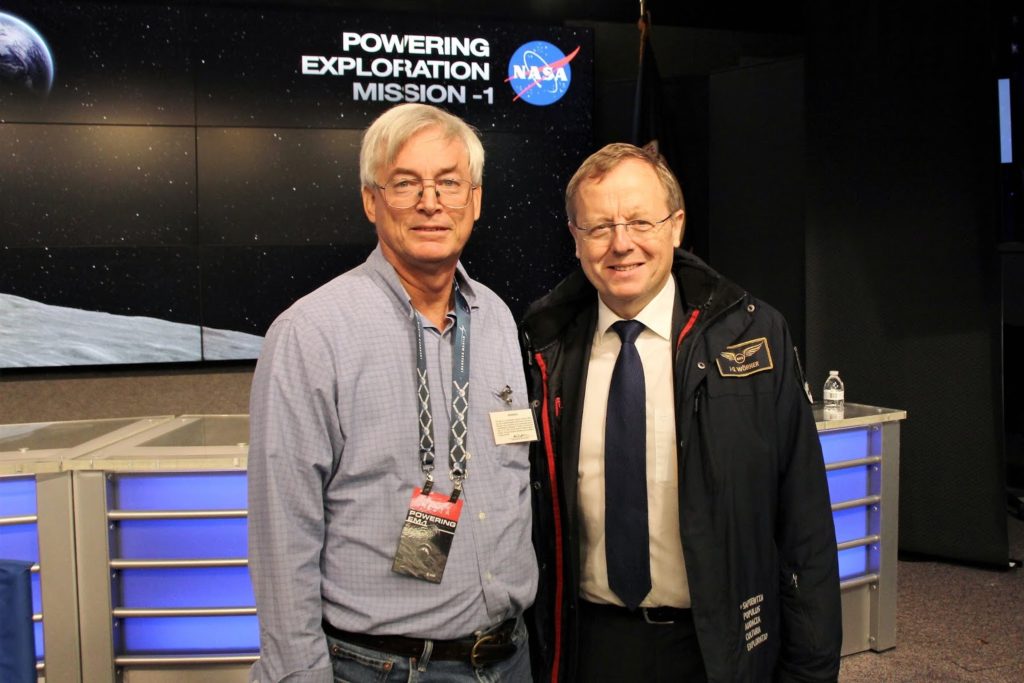

ESA Director General Jan Wörner at the “Powering EM-1” KSC media event.

“We will go in a totally different way to the moon. Not in competitive

manner but in a very cooperative manner … to motivate the future.”

we celebrate the delivery of the European Service Module, said NASA

Administrator Jim Bridenstine.

USA is very grateful for our partners at the European Space Agency and all its

member nations.”

“This

is a momentous occasion where we will have the opportunity to fly into deep

space. And the European Service Module is a huge element of this architecture.”

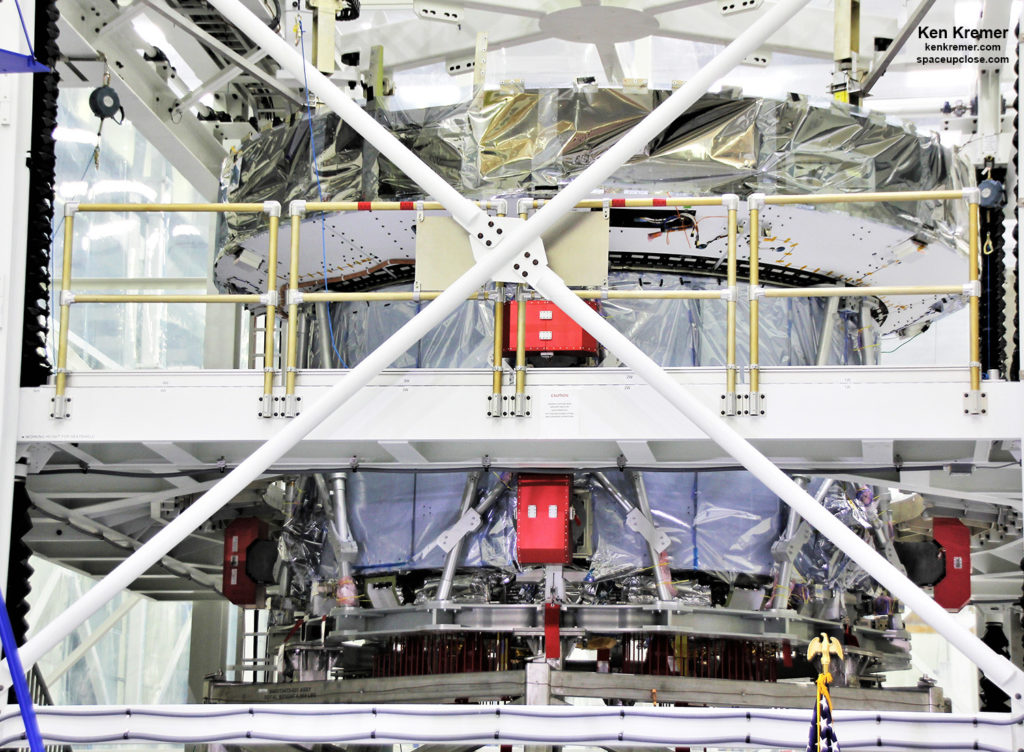

Enjoy our exclusive ESM event

photos at KSC’s Neil Armstrong

Operations and Checkout building.

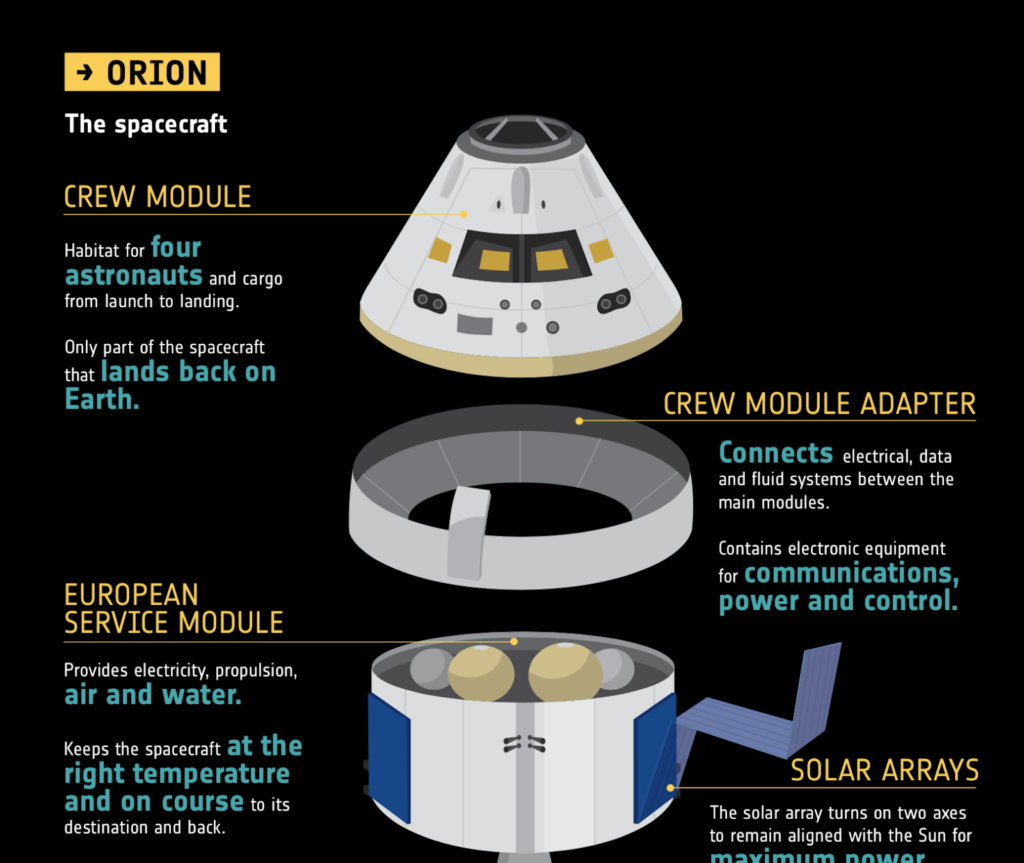

The cylindrically-shaped

European Service Module ESM-1 is the critical ‘powerhouse’ element that will

supply NASA’s human-rated Orion spacecraft with electricity, propulsion,

thermal control, air and water and propel it on its first voyage to the the Moon and 40,000 miles (64,000 km) beyond atop SLS-1 during

EM-1 from KSC pad 39B.

|

|

Graphic outlining European Service Module for NASA’s Exploration

Mission-1 with Orion human-rated spacecraft and Space Launch System rocket launch to the Moon in 2020. Credit: ESA/Airbus |

“This

powerhouse element is what we need to go farther than ever before,” said Mark Kirasich, NASA’s

Orion program manager.

“In

space the two halves must operate flawlessly.”

“It’s a great day @NASAKennedy with

our @esaspaceflight @AirbusSpace @LockheedMartin

partners with the delivery of the #OrionESM !” tweeted Kirasich.

ESM-1 was funded and developed by the European Space Agency (ESA) and

manufactured by prime contractor Airbus in Bremen, Germany and Turin, Italy with components supplied by

companies all over Europe.

After

years of separate development the two main components are finally together in

the same place for mating and more!

“Finally together! @NASA_Orion‘s

service and crew modules are both at @NASAKennedy,

and this is just the beginning – the first leg of an exciting #JourneyToTheMoon,”

tweeted ESA.

The

implications here are huge because this marks the first

time that NASA “will use a European-built system as a critical element to power

an American spacecraft, extending the international cooperation of the

International Space Station into deep space.”

Eventually

future ESMs will power Orion astronauts to the Moon and beyond on mission to

deep space starting with Exploration Mission-2 (EM-2) as soon as 2022 after

life support and other systems are incorporated.

ESM

serves the same role as the Apollo Service Module (SM) during NASA’s Apollo Moon

landing missions in the 1960s and 1970s.

Orion and SLS

are under development by NASA to lead humanity back to a permanent presence

at the Moon

together with partners including Europe and potentially Russia, Canada and Japan.

NASA’s

Gateway human tended lunar orbiting outpost is key to NASA human ‘Return to the

Moon’ architecture says NASA Administrator Jim Bridenstine.

“We are in a good place to be a partner for

the lunar Gateway,” says Jan Wörner. r

ESM-1 aerived stateside at the Kennedy Space Center, FL, on Nov. 6, from its manufacturing

facility in Bremen, German after flying here aboard a huge Antanov An-124 cargo

jet touching down gracefully at approximately 11:34 a.m. EST at the Shuttle

Landing Facility – as witnessed by Space UpClose with photos taken from Titusville,

FL.

|

| Credit: Ken Kremer/kenkremer.com/spaceupclose.com |

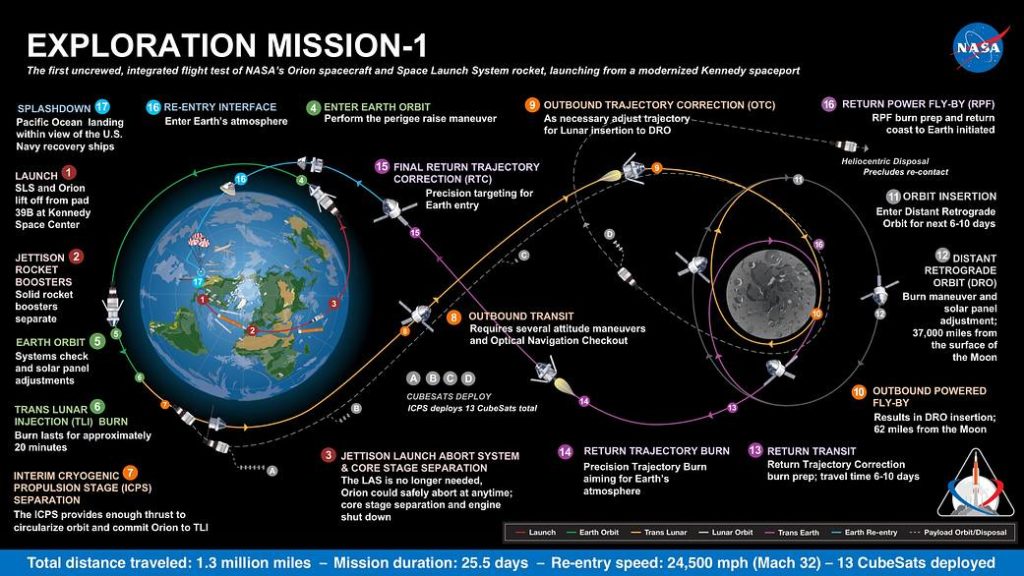

Orion’s first mission launches to the Moon on

the uncrewed EM-1 test flight in 2020 on NASA’s Space Launch System (SLS) mammoth

rocket.

|

| Graphic outlining NASA’s Exploration Mission-1 with Orion human-rated spacecraft and Space Launch System rocket launch to the Moon in 2020. Credit: NASA |

The

next step is to test, connect and integrate the two hardware components together

with NASA’s Orion Crew Module stacked atop ESA’s Orion Service Module – just like the Apollo Command and Service modules.

That effort

begins now inside the Neil Armstrong Operations & Checkout (O & C) high bay at KSC where the crew module is being manufactured by prime contractor

Lockheed Martin.

The cylindrically

shaped ESM arrived at the entrance to the O & C later the same day in flew

here aboard the Antonov.

“Come on in; we’ve been waiting for you! The @esa @AirbusSpace European

Service Module is at the door of the @NASAKennedy Neil Armstrong Operations and Checkout Building!”

tweeted Mark Kirasich, NASA’s Orion program manager.

“Engineers will complete functional checkouts to

ensure all elements are working properly before it is connected to the Orion

crew module. Teams will weld together fluid lines to route gases and fuel and

make electrical wiring connections,” NASA reported.

The

team is already hard at work and had already connected the Orion Crew Module Adapter

to the top of ESM-1 by the day of the event using 192 bolts that “are needed to keep the structure together and withstand the

immense forces of launch and spaceflight.”

by technicians to attach the Crew Adapter to ESM-1 with the 192 bolts was arduous

and excruciating at the complex interfaces between them, explained Philippe

Berthe, ESA’s ESM program manager for Orion.

check that everything is perfectly aligned as required.

enables them to start working on connections for

power, data and welding the pipes for the fluids such as water and fuel between

the two main modules.

EM-1 crew module will be connected next to the Adapter and ESM-1.

For the thousands of miles (km) journey across

the Atlantic Ocean the ESM “was packed in a custom-built container that keeps

the environment inside within acceptable limits for transportation,” said ESA.

contractor Airbus Defence & Space designed and manufactured the ESM at

facilities in Bremen, Germany and Turin, Italy with over 20,000 parts provided

by companies across ESA’s partner nations. The design builds on heritage from

ESA’s now retired Automated Transfer Vehicle (ATV) which

served as a cargo freighter for the ISS.

tall ESM provides power, propulsion, life support and consumables for the Orion

crew capsule and the astronauts – including oxygen, nitrogen

and water – on the first integrated flight with the SLS heavy lift booster on EM-1.

|

|

Orion Spacecraft

modules. Credits: ESA |

The service module is equipped with four

giant solar array wings that span 19 meters when deployed and provide

enough electricity to power two three-bedroom homes, as well as the orbital

maneuvering system.

Each solar wing measures 2 m wide by 7 m in

length. The four wings contain 15,000 solar cells to convert light into the electricity

that powers Orion.

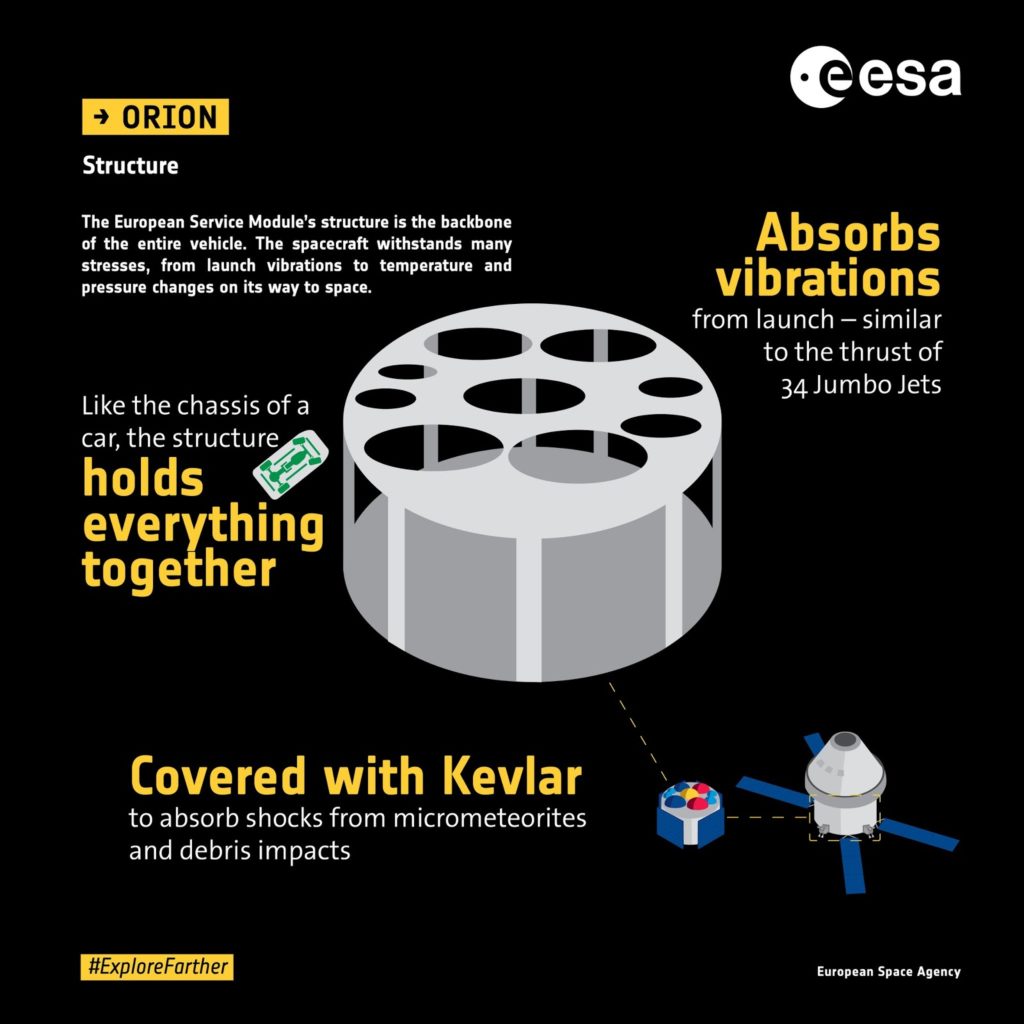

Radiators and heat exchangers help maintain comfortable

temperatures, “while the module’s structure is the backbone of the entire

vehicle, like a car chassis,” according to ESA.

One of the key challenges was keeping the ESM

spacecraft mass within tight limits.

“If you want to go far, you must go light,” explained Philippe

Berthe.

“We have been on a 7-year diet to get

everything included. So we took some short cuts for EM-1 because of the schedule.

But we have plans for the future modules to be compliant.”

“We still need to lose some weight for EM-2 and

beyond.”

“EM-2 is mass constrained. EM-1 was not.”

the service modules for EM-1 and EM-2 to fulfil their budgetary obligations to the International Space

Station through 2024.

The main engine ignites to provide the powerful

burns to propel insert Orion into and out of lunar orbit and return to Earth. The module is equipped with 33 engines altogether.

repurposed Space Shuttle Orbital Maneuvering System (OMS) engine. It has flown 19 times in space before on three

shuttle orbiters including Challenger, Discovery and Atlantis from 1984 to its

last flight in space in 2002 on the STS-112 mission and provides 25.7 kN thrust.

future.

upcoming Orion mission,” Oliver Juckenhöefel, Airbus

VP Bremen told Space UpClose in an interview at the KSC event.

develop something new and they are available to use now.”

and mated the usit will be shipped to NASA’s Plum Brook facility for rigorous acoustic

and vacuum testing in the world’s largest

thermal vacuum chamber.

Orion for testing when it arrives at Plum Brook Station next summer,” says

Janet Kavandi, Director of NASA’s Glenn Research Center in Cleveland, Ohio and

three-time shuttle astronaut.

Watch for Ken’s continuing onsite coverage of NASA, SpaceX, ULA,

Boeing, Lockheed Martin, Northrop Grumman and more space and mission reports

direct from the Kennedy Space Center, Cape Canaveral Air Force Station, Florida

and Wallops Flight Facility, Virginia.

and human spaceflight news: www.kenkremer.com –www.spaceupclose.com – twitter

@ken_kremer – email: ken at kenkremer.com

scientist, journalist and photographer based in the KSC area.

Ken’s photos are for sale and he is available for lectures and outreach events

|

|

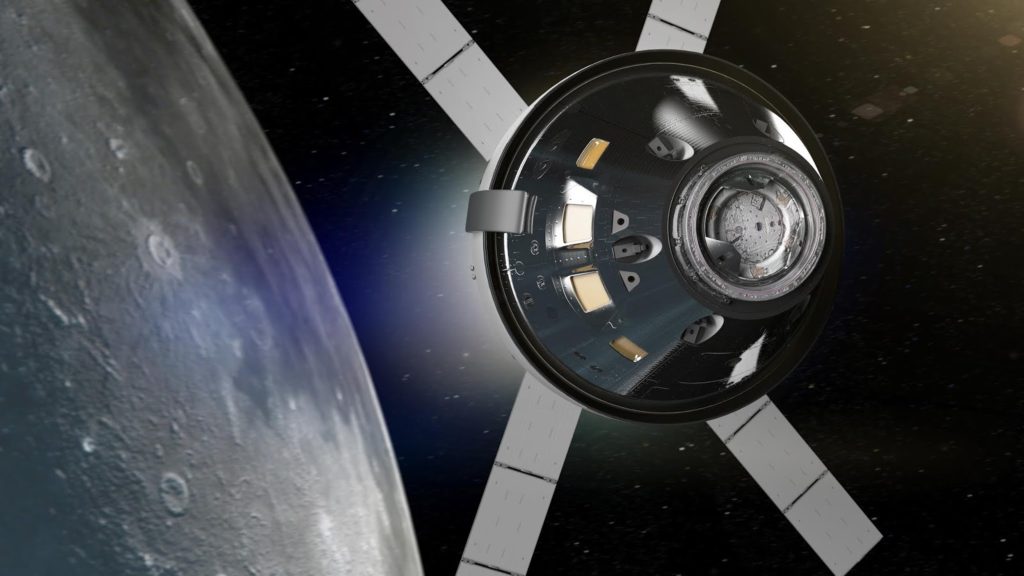

Artists concept of NASA’s Orion spacecraft

mission to the Moon. Credit: NASA |

|

| ESA Director General Jan Wörner and Ken Kremer (l) Space UpClose chat about the European Service Module unveiled at NASA’s Kennedy Space Center on Nov. 16, 2018 |