|

|

Crews

delivered the last of four RS-25 engines for Artemis 1, the first flight of NASA’s Space Launch System (SLS) rocket and the Orion spacecraft, from NASA’s Stennis Space Center near Bay St. Louis, Mississippi, to NASA’s Michoud Assembly Facility in New Orleans, June 27, 2019. The Aerojet-Rocketdyne engines are lined up side-by-side on June 28 and will be installed into the SLS engine section Summer 2019. Credit: Ken Kremer/kenkremer.com/spaceupclose.com |

Ken Kremer — SpaceUpClose.com & RocketSTEM – 30 Jun 2019

NASA Michoud Assembly Facility, LA – The massive core stage for the first flight of NASA’s mammoth Space Launch

System (SLS) rocket and the Orion deep space crew capsule for the Artemis 1 mission to the moon and back is finally taking shape at NASA’s sprawling Michoud Assembly Facility (MAF) in New Orleans.

The last of the four RS-25 engines that will power the core stage were delivered from NASA’s Stennis Space Center near Bay St. Louis, Mississippi, to Michoud on June 27, 2019 – and I visited them Up Close the next day on Friday, June 28 as part of our media tour. And they were a magnificent sight to behold!

Working in parallel NASA and prime SLS contractor Boeing achieved another significant milestone in the manufacture of the core stage in June when four-fifths of the huge stage destined for Artemis 1 were assembled together at last.

Enjoy our photos of the RS-25 engines, the core stage, the engine section and a tour around NASA’s Michoud Assembly Facility to observe assorted flight hardware and components being

assembled right now for the first two SLS launches, namely on the Artemis-1 and Artemis-2 missions – as well as NASA’s one of a kind Pegasus barge that will transport the vehicle between NASA centers for testing and eventually to the launch site at the Kennedy Space Center in Florida.

Check back as the gallery grows.

|

|

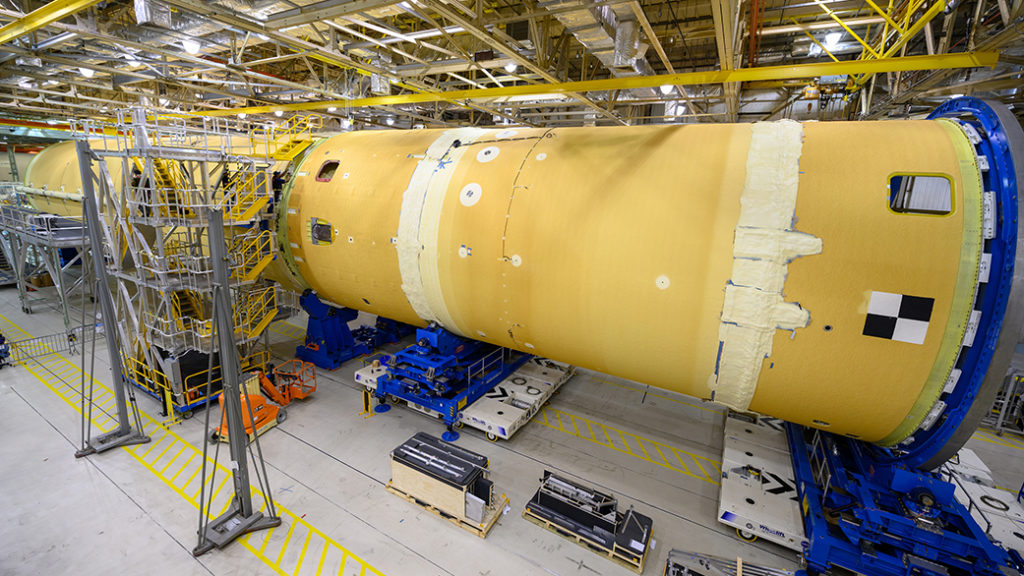

The core stage for NASA first Space Launch System (SLS) rocket for the Artemis 1

mission is being manufactured at NASA’s Michoud Assembly Facility in New Orleans as seen here on June 28, 2019. The RS-25 engines will be installed into the SLS engine section Summer 2019. Credit: Ken Kremer/kenkremer.com/spaceupclose.com |

NASA Deputy Administrator James Morhard was on hand with the media for an update and facility tour during his first visit to Michoud on June 28.

Morhard told Space UpClose that NASA is working hard with congress to obtain the $1.6 Billion

budget boost to the Fiscal Year 2020 budget request for NASA.

The money is required to kickstart development of a human a human lunar lander and achieve the Trump Administrations new goal of achieving an American lunar landing by 2024 at the

south pole with the first woman and next man from NASA’s astronaut corps on the Artemis-3 mission.

|

|

NASA Deputy Administrator James Morhard speaks

with media in front of flight hardware for Artemis 1 during his first visit to NASA’s Michoud Assembly Facility in New Orleans Friday, June 28, 2019. Michoud is manufacturing the core stage for NASA’s Space Launch System (SLS) rocket. Credit: Ken Kremer/kenkremer.com/spaceupclose.com |

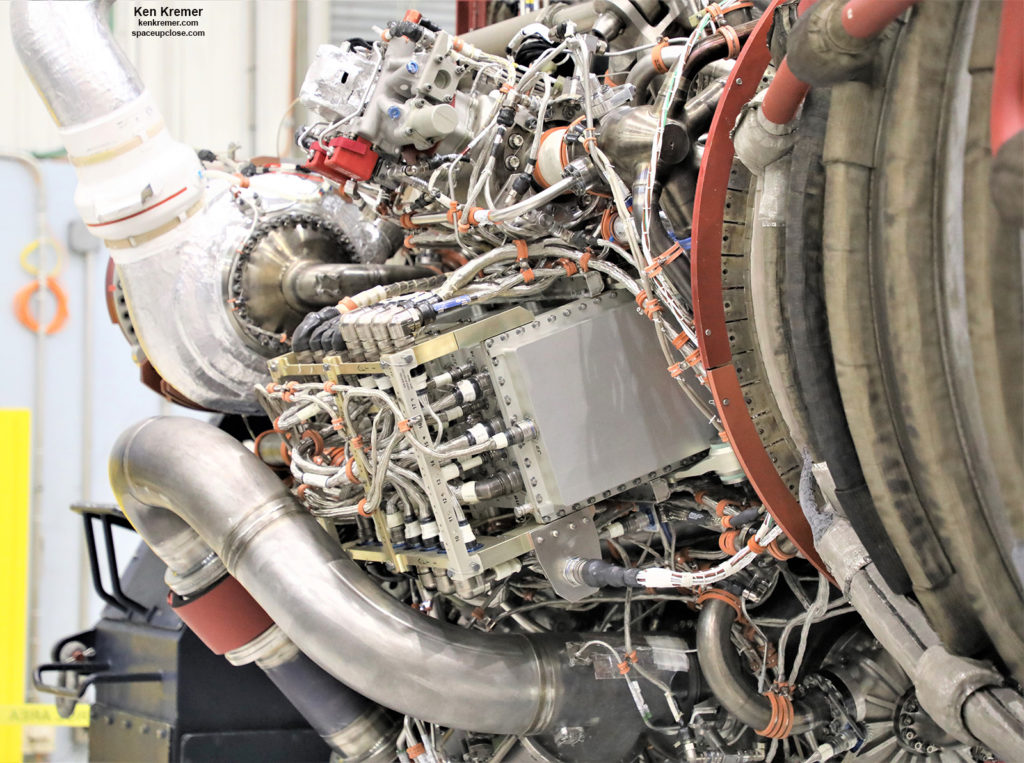

The RS-25 engines are recycled from NASA’s space shuttles where clusters of three then called Space Shuttle Main Engines or SSMEs powered the orbiters and propelled 135 missions to space.

NASA now has 16 RS-25 engines in inventory. They have been modified and upgraded to power SLS. They were originally built and then refurbished by Aerojet Rocketdyne.

|

|

UpClose

view of an RS-25 engine destined for Artemis 1, the first flight of NASA’s Space Launch System (SLS) rocket and the Orion spacecraft after delivery to NASA’s Michoud Assembly Facility in New Orleans. The Aerojet Rocketdyne engine seen on June 28 will be installed into the SLS engine section Summer 2019. Credit: Ken Kremer/kenkremer.com/spaceupclose.com |

Among the significant upgrades is the new engine controller which functions as the ‘brain’ to command the engines. See our photos.

|

|

UpClose

view of the engine controller which serves as the brain that commands this RS-25 engine destined for Artemis 1, the first flight of NASA’s Space Launch System (SLS) rocket and the Orion spacecraft after delivery to NASA’s Michoud Assembly Facility in New Orleans. The Aerojet Rocketdyne engine seen on June 28 will be installed into the SLS engine section Summer 2019. Credit: Ken Kremer/kenkremer.com/spaceupclose.com |

The RS-25 engines have been ready for installation since Oct. 2017 when they completed qualification testing at Stennis.

The maiden launch of SLS will fly an uncrewed Orion on the Artemis 1 test flight – perhaps by late 2020 but more likely in 2021.

Whenever it does soar to space NASA’s gargantuan Moon to Mars SLS megarocket will become the most powerful rocket in human history – spewing some 8.8 million pounds of liftoff thrust

overall.

It’s a massive undertaking to manufacture SLS and get the 322 foot tall rocket ready to rumble.

So Michoud is a beehive of activity as workers assemble the varied components in multiple highbays, welders and stations in various highbays spanning the facility which is so big – acres and acres across – it requires a tram to get around and visit.

The next step at Michoud will be to complete the assembly of the core stage by finishing construction and outfitting of the bottom engine section and integrating it onto the bottom of core stage 1.

|

|

Crews

delivered the last of four RS-25 engines for Artemis 1, the first flight of NASA’s Space Launch System (SLS) rocket and the Orion spacecraft, from NASA’s Stennis Space Center near Bay St. Louis, Mississippi, to NASA’s Michoud Assembly Facility in New Orleans on June 27, 2019. The Aerojet Rocketdyne engines are lined up side-by-side on June 28 and will be installed into the SLS engine section Summer 2019. Credit: Ken Kremer/kenkremer.com/spaceupclose.com |

The four RS-25 engines will then be installed by technicians and engineers from NASA and Aerojet Rocketdyne onto the bottom engine section of the core stage starting later this

summer.

And they are all currently in close proximity, just around the corner from one another.

Core Stage 1 is resting horizontally just behind the wall from the four RS-25 engines.

And the engine section is resting vertically in a big jig surrounded by scaffolding right next to the

core stage.

NASA hopes to complete the assembly of Core Stage 1 by December in order to have any chance of achieving a launch before the end of 2020 and the end of President Trump’s

current term in office.

After that per the current schedule NASA will conduct a full duration ‘green run’ engine fire test

of the completed core stage at Stennis to fully confirm its readiness for flight. But that test will require six months of intense effort work.

NASA officials have yet to decide whether to proceed as planned or whether to curtail or change the test.

Until NASA officials make a final decision, the green run test is still on track to be carried out, NASA told Space UpClose.

But SLS is years behind schedule and over budget and Boeing has encountered numerous hardware manufacturing problems and difficulties resulting in substantial delays.

NASA originally hoped to launch SLS-1 by the end of 2017 – so the rocket is at least 3 years behind schedule. And I’ve been visiting and documenting progress over the years.

In its current configuration the core stage measures 190 feet in length equivalent to about the size of 12 cars parked end-to-end.

So far the 80% complete core stage comprises the forward skirt that houses the rockets flight computers and the upper liquid oxygen (LOX) and lower liquid hydrogen propellant tanks which are joined together by the intertank that holds more avionics.

“This milestone brings the Space Launch System closer to launching the first Artemis mission,” said John Honeycutt, SLS program manager, regarding the core stage assembly. “The SLS rocket team is laser focused on building the rocket not only for the first flight but also rockets for the second and third Artemis missions that will send astronauts to the Moon.”

Final core stage 1 assembly starts now.

When complete, the core stage will measure 212 feet tall (64.6 meters) from tip to tip and 27.6 feet (8.8 meters) in diameter.

It weighs approximately 188,000 lbs (85,275 kg) empty and is constructed from Aluminum 2219.

The core stage is derived from the Space Shuttle External Tank (ET) – all of which were also built at Michoud for 135 space shuttle launches. The core stage is about 20% longer than the ET.

The LOX/LH2 fueled RS-25 engines are a wonder of engineering from the Space

Shuttle era and designed to be reusable from the start.

However for SLS they will be utilized for their final time and discarded at the conclusion of the

launch sequence and ditched in the ocean since the core stage cannot land – unlike the shuttle orbiters.

The 4 RS-25 engines for the SLS Artemis 1 core stage have flown on a combined 21 space shuttle missions. They are engines E2045, E2056, E2058, and E2060.

“For SLS, they have been upgraded with new controllers, to perform under SLS environments and with nozzle insulation, for protection and prevention of metal overheating during launch and flight,” says NASA.

The engine controllers regulate the thrust levels of each engine and monitor health and performance. See our photos.

At launch the RS-25 engines will produce a combined 2 million pounds of liftoff thrust.

Each engine offers 512,000 pounds of thrust – which is 109% of their operational thrust level and

higher than the 104.5% thrust commonly used during the shuttle era.

They will fire non-stop along with the two side mounted solid rocket boosters for approximately eight and one half minutes all the way to orbit.

The RS-25s measure 14 feet long and 8 feet in diameter and weigh 7775 pounds.

|

|

NASA’s

Pegasus barge ready to haul an SLS LOX structural test article on June 28, 2019 from NASA Michoud to NASA Marshall for structural testing. Credit: Ken Kremer/kenkremer.com/spaceupclose.com |

Artemis 1

will be the first mission launching Orion on the SLS rocket from Kennedy’s

Launch Pad 39B. The mission will take Orion thousands of miles past the Moon on

an approximately three-week test flight.

Orion will return to Earth and splashdown in the Pacific Ocean off the coast of California, where it will be retrieved and returned to Kennedy.

Watch for Ken’s continuing onsite coverage of NASA, SpaceX, ULA, Boeing, Lockheed Martin, Northrop Grumman and more space and mission reports direct from the Kennedy Space Center, Cape Canaveral Air Force Station, Florida and Wallops Flight Facility, Virginia.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news: www.kenkremer.com –www.spaceupclose.com – twitter @ken_kremer

– email: ken at kenkremer.com

Dr. Kremer is a research scientist and journalist based in the KSC area, active in outreach and interviewed regularly on TV and radio aboutspace topics.

………….

Jul 19/20: Quality Inn Kennedy Space Center, Titusville,

FL, evenings. Learn more about the upcoming/recent NASA Orion Ascent-2 Abort test Falcon Heavy, NASA 2024 Moon landing goal, SpaceX Starlink-1, SpaceX Falcon 9/CRS-17

launch to ISS, SpaceX Demo-1 launch/test failure, SpaceX Beresheet launch, NASA missions, ULA Atlas & Delta launches, Northrop Grumman Antares, SpySats and more

Ken will display his photos for sale