Engineers and technicians at NASA’s Michoud Assembly Facility in New Orleans have structurally mated the first of four RS-25 engines to the core stage for NASA’s Space Launch System (SLS) rocket that will help power the first Artemis mission to the Moon. Credit: NASA/Jude Guidry

For SpaceUpClose.com & RocketSTEM

KENNEDY SPACE CENTER, FL/MICHOUD ASSEMBLY FACILITY, LA – The first of four RS-25 engines that will ultimately help power the first launch of NASA’s Space Launch System (SLS) rocket to the Moon on the first Artemis mission has been mated to the mammoth rockets core stage by engineers and technicians at NASA’s Michoud Assembly Facility in New Orleans.

NASA announced the joining of the first RS-25 engine onto the bottom engine section of the 212-foot-long SLS core stage on Oct. 22.

The engine attachment work was led by lead engine contractor Aerojet Rocketdyne in coordination with NASA and SLS lead contractor Boeing.

Major structural assembly of this first SLS core stage itself was only just completed a month ago on Sept. 19 by Boeing workers at Michoud after years of effort and much delay after they attached the last of five sections of the 212-foot-tall core stage – namely the bottom engine section which is one of the most complicated pieces of hardware for the SLS rocket and has been problematic to design and build and caused much of the delay.

The Boeing team bolted the engine section to the stage’s liquid hydrogen propellant tank at the base of the core stage.

The next steps in the multistep engine installation process is to integrate the propulsion, electrical and avionics systems and complete the propulsion functional tests.

The entire installation process will be repeated for each of the three remaining RS-25 engines.

“The engines, located at the bottom of the core stage in a square pattern, are fueled by liquid hydrogen and liquid oxygen. During launch and flight, the four engines will fire nonstop for 8.5 minutes, emitting hot gases from each nozzle 13 times faster than the speed of sound,” say NASA officials.

Altogether the core stage will produce a combined 2 million pounds of thrust powered by the four RS-25 engines fueled by liquid hydrogen and liquid oxygen.

The RS-25 engine installation by the Aerojet-Rocketdyne team will take several months with completion of all four expected in December.

Thereafter the core stage will be shipped on the Pegasus barge to NASA Stennis Space Center to carry out the Green Run testing involving a full duration engine test to qualify the stage for launch on the Artemis 1 mission.

The green run test campaign will last about six months or so.

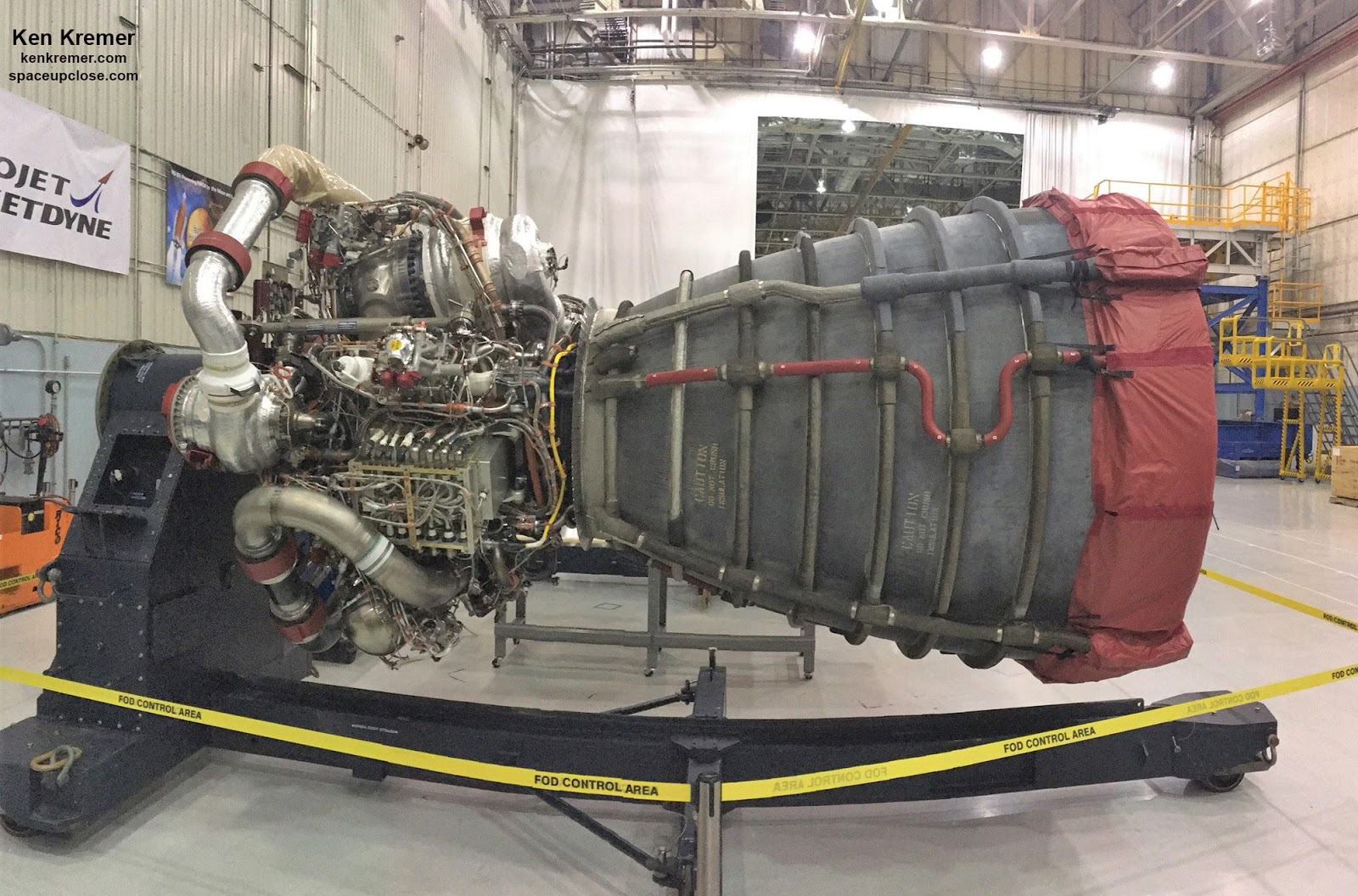

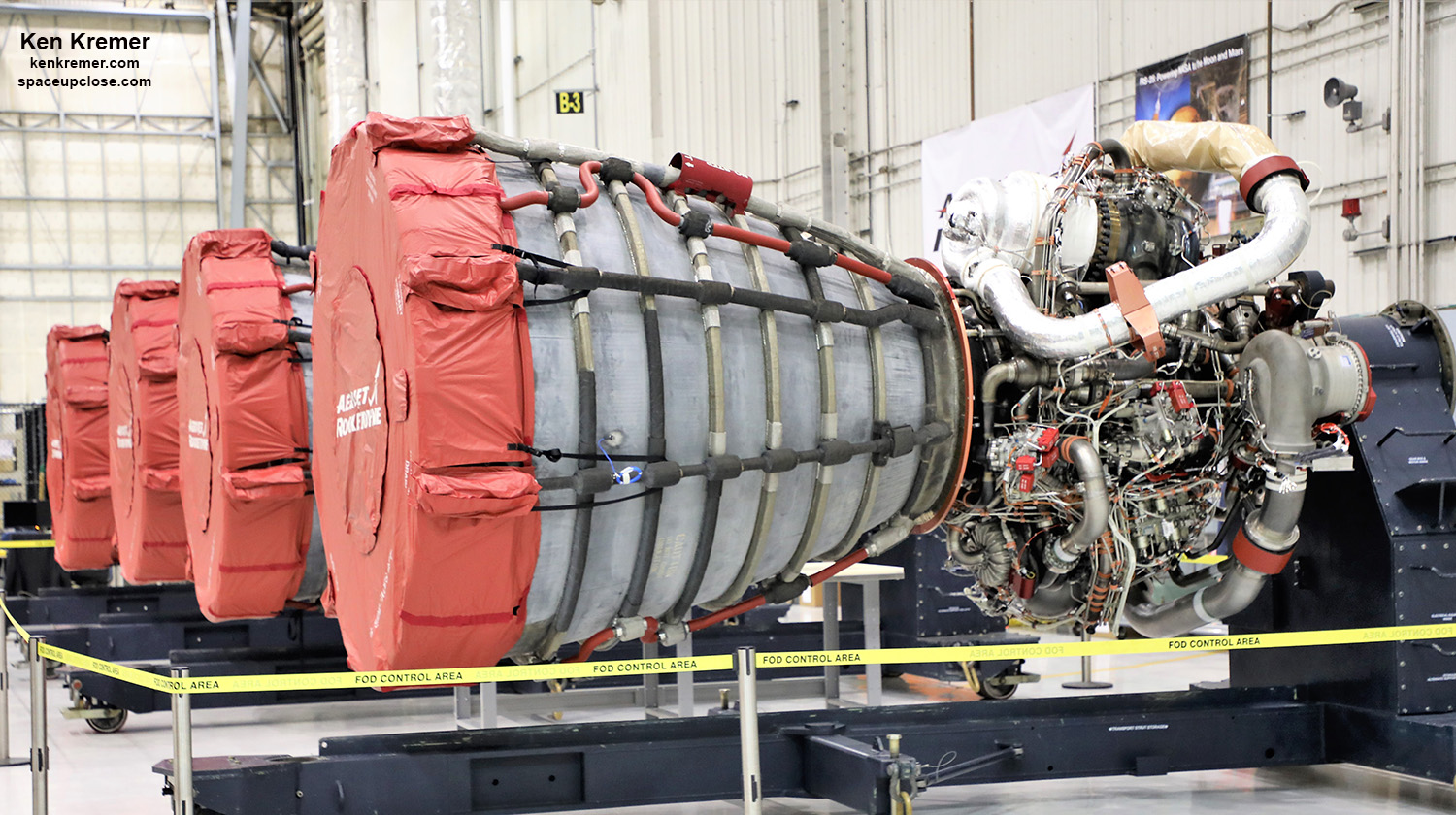

I visited Michoud in late June to see the core stage which at that time was four fifths complete and about 190 feet in length – as well as the four RS-25 engines Up Close that had just been delivered from Aerojet Rocketdyne’s facility at NASA’s Stennis Space Center near Bay St. Louis, Mississippi, to Michoud on June 27, 2019. And they were a magnificent sight to behold!

See our Space UpClose photos herein from our Michoud media tour on June 28.

The SLS core stage is the largest rocket stage the agency has built since the Saturn V that sent Apollo astronauts to the Moon.

The SLS-1 core stage will propel the Artemis I mission on the first integrated flight of the SLS rocket and NASA’s Orion deep space human spacecraft to the Moon – as soon as late 2020 but more likely in early 2021.

The overall goal is to build the rockets for NASA’s Artemis moon exploration program aimed at landing US astronauts on the Moon by 2024 at the lunar south pole – including the first woman and the next man.

“SLS is part of NASA’s backbone for deep space exploration, along with Orion and the Gateway in orbit around the Moon. SLS is the only rocket that can send Orion, astronauts and supplies to the Moon on a single mission.”

The core stage engine section “is the attachment point for the four RS-25 engines and the two solid rocket boosters that produce a combined 8.8 million pounds of thrust to send Artemis I to space.

“In addition, the engine section includes vital systems for mounting, controlling and delivering fuel from the stage’s two liquid propellant tanks to the rocket’s engines.”

The RS-25 engines are recycled from NASA’s space shuttles where clusters of three then called Space Shuttle Main Engines or SSMEs powered the orbiters and propelled 135 missions to space.

NASA now has 16 RS-25 engines in inventory. They have been modified and upgraded to power SLS. They were originally built and then refurbished by Aerojet Rocketdyne.

Among the significant upgrades is the new engine controller which functions as the ‘brain’ to command the engines. See our photos.

The RS-25 engines have been ready for installation since Oct. 2017 when they completed qualification testing at Stennis.

But SLS is years behind schedule and billions over budget and Boeing has encountered numerous hardware manufacturing problems and difficulties resulting in substantial delays.

NASA originally hoped to launch SLS-1 by the end of 2017 – so the rocket is at least 3 years behind schedule. And I’ve been visiting and documenting progress over the years.

NASA will conduct a full duration ‘green run’ engine fire test of the completed core stage at Stennis to fully confirm its readiness for flight on Artemis 1. But that test will require six months of intense work by NASA and contractor teams.

Meanwhile the Orion Artemis 1 crew capsule is nearing completion nearby in the Operations and Checkout building I recently visited at KSC.

Watch for our upcoming Orion update.

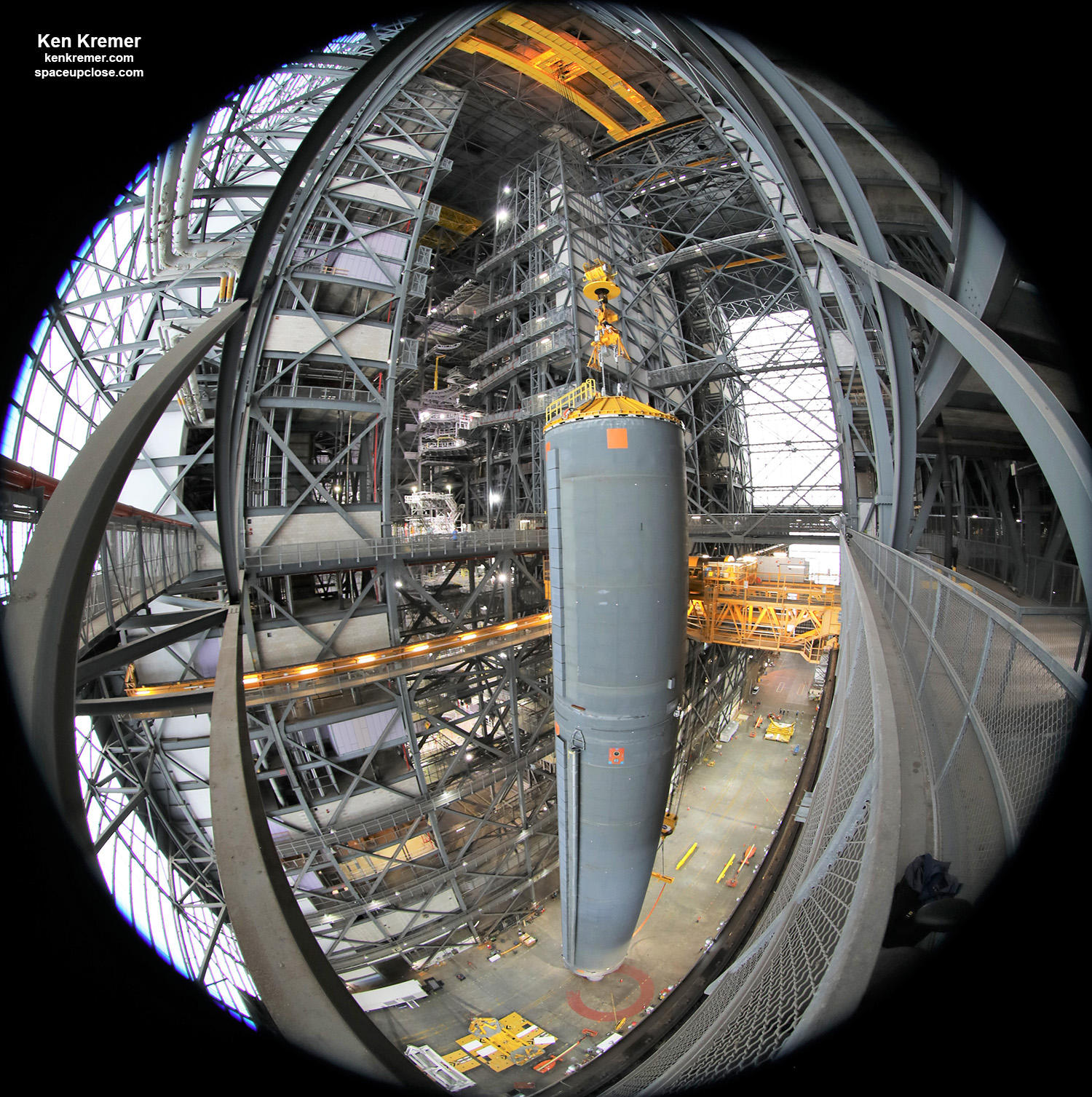

Furthermore the recently arrived and massive 212 foot long, 228,000 pound core stage Pathfinder mock-up for NASA’s Space Launch System (SLS) megarocket was lifted to the vertical position inside the Vehicle Assembly Building’s (VAB) transfer aisle and then into High Bay 3 this past week at NASA’s Kennedy Space Center – by KSC and contractor teams carrying our critical work to practice offloading, moving, and stacking maneuvers required for assembly when the real SLS hardware for launch of the first Artemis moon mission arrives sometime around the middle of next year in 2020.

Pegasus and Pathfinder sailed into and docked at the Turn Basin wharf by the world famous countdown clock at Kennedy nearly three weeks ago Sept. 27 after being towed by ocean-going and river-going tugboats for a nearly 1000-mile and week-long trek from NASA’s Stennis Space Center in Mississippi to KSC.

More about the RS-25 engines:

The LOX/LH2 fueled RS-25 engines are a wonder of engineering from the Space Shuttle era and designed to be reusable from the start.

However for SLS they will be utilized for their final time and discarded at the conclusion of the launch sequence and ditched in the ocean since the core stage cannot land – unlike the shuttle orbiters.

The 4 RS-25 engines for the SLS Artemis 1 core stage have flown on a combined 21 space shuttle missions. They are engines E2045, E2056, E2058, and E2060.

“For SLS, they have been upgraded with new controllers, to perform under SLS environments and with nozzle insulation, for protection and prevention of metal overheating during launch and flight,” says NASA.

The engine controllers regulate the thrust levels of each engine and monitor health and performance. See them in our photos.

At launch the RS-25 engines will produce a combined 2 million pounds of liftoff thrust.

Each engine offers 512,000 pounds of thrust – which is 109% of their operational thrust level and higher than the 104.5% thrust commonly used during the shuttle era.

They will fire non-stop along with the two side mounted solid rocket boosters for approximately eight and one half minutes all the way to orbit.

The RS-25s measure 14 feet long and 8 feet in diameter and weigh 7775 pounds.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news: www.kenkremer.com –www.spaceupclose.com – twitter @ken_kremer – email: ken at kenkremer.com

Dr. Kremer is a research scientist and journalist based in the KSC area, active in outreach and interviewed regularly on TV and radio about space topics.

………….

Ken’s photos are for sale and he is available for lectures and outreach events