For SpaceUpClose.com & RocketSTEM

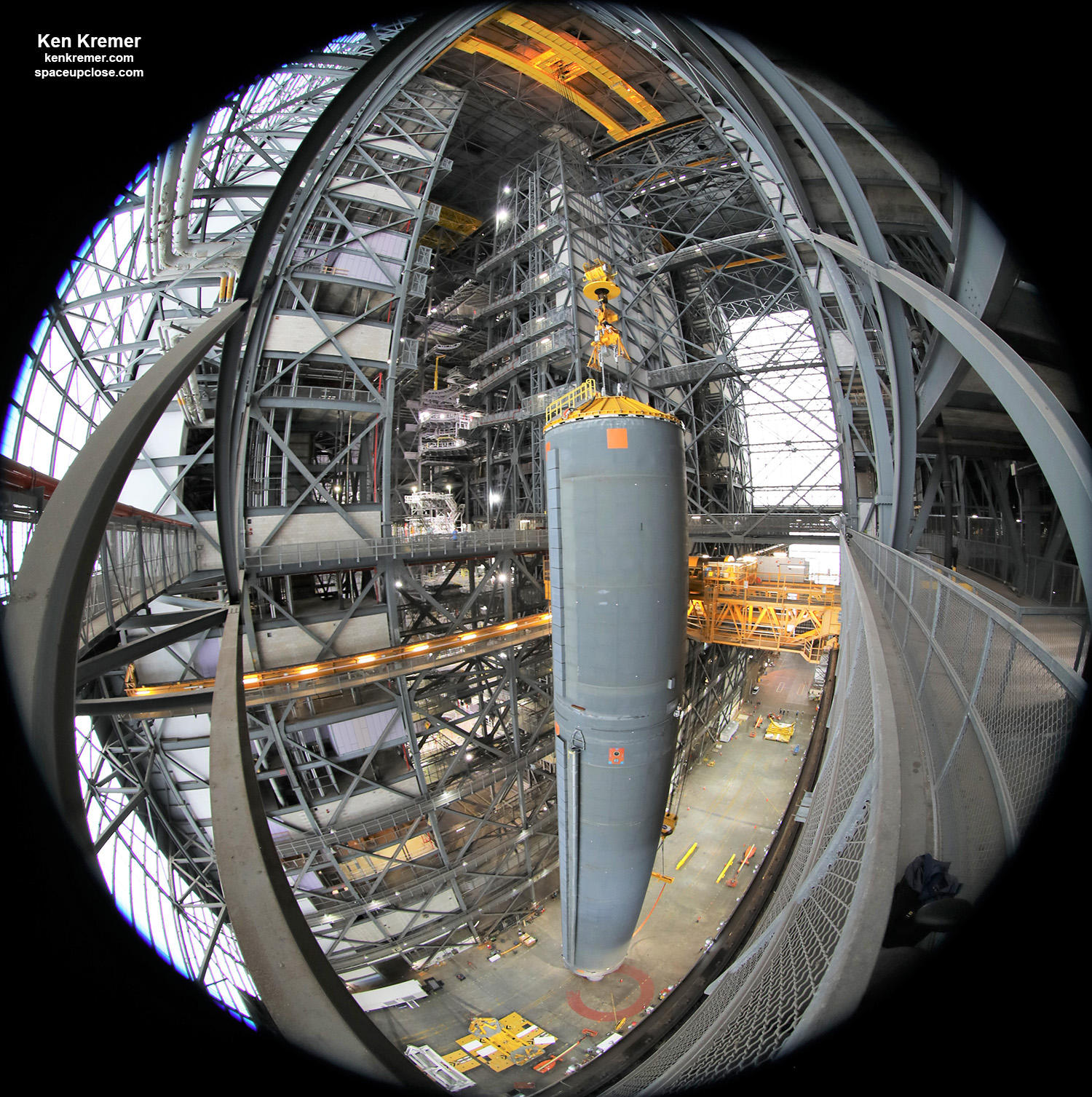

KENNEDY SPACE CENTER, FL – The recently arrived and massive 212 foot long, 228,000 pound core stage Pathfinder mock-up for NASA’s Space Launch System (SLS) megarocket was lifted to the vertical position inside the Vehicle Assembly Building’s (VAB) transfer aisle and then into High Bay 3 this past week at NASA’s Kennedy Space Center – by KSC and contractor teams carrying our critical work to practice offloading, moving, and stacking maneuvers required for assembly when the real SLS hardware for launch of the first Artemis moon mission arrives sometime around the middle of next year in 2020.

The recently arrived Pathfinder core stage mockup here at KSC is in the midst of some 4 weeks of vital work in support of NASA’s Artemis moon exploration program aimed at landing US astronauts on the lunar south pole by 2024 – including the first woman ever as well as the next man.

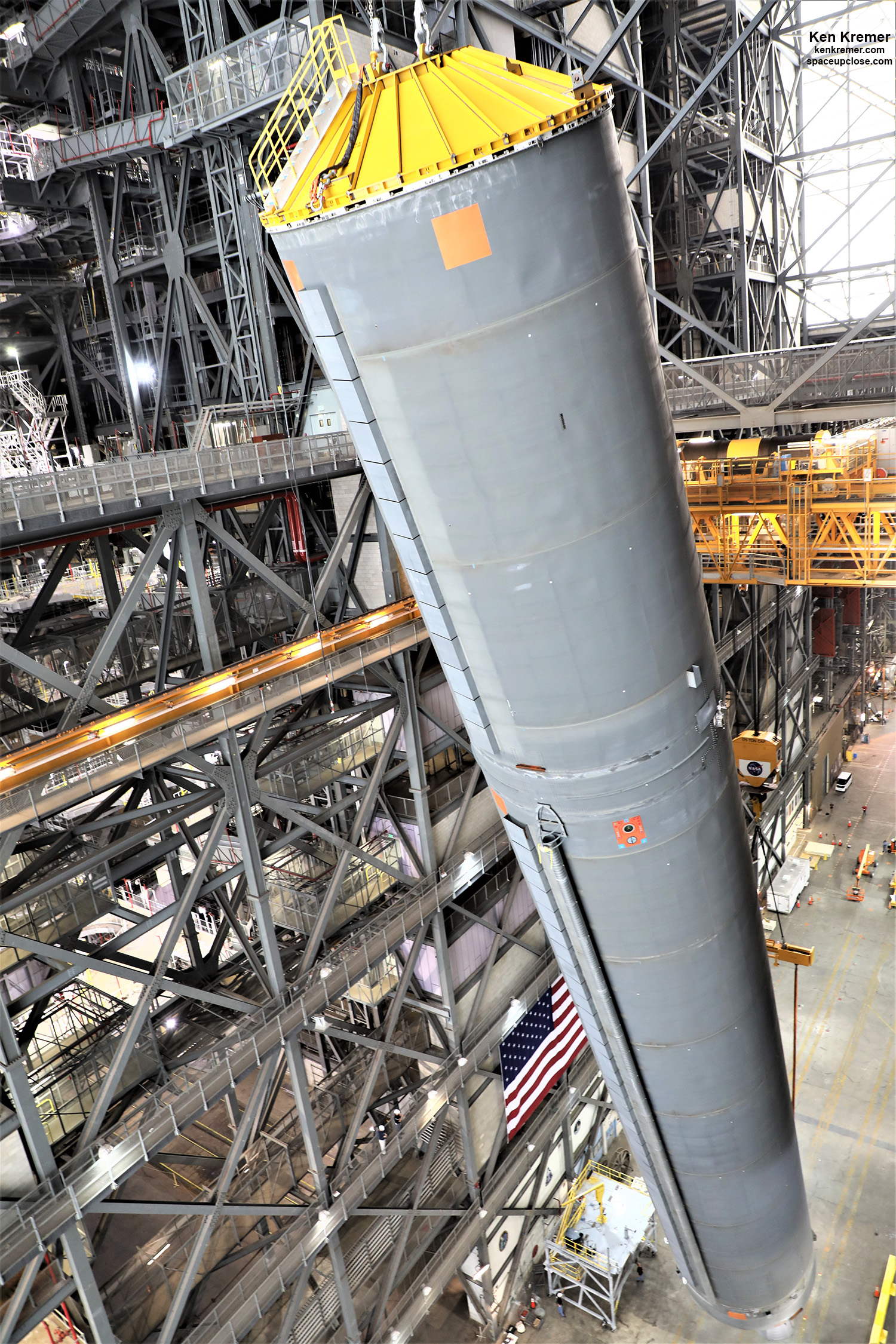

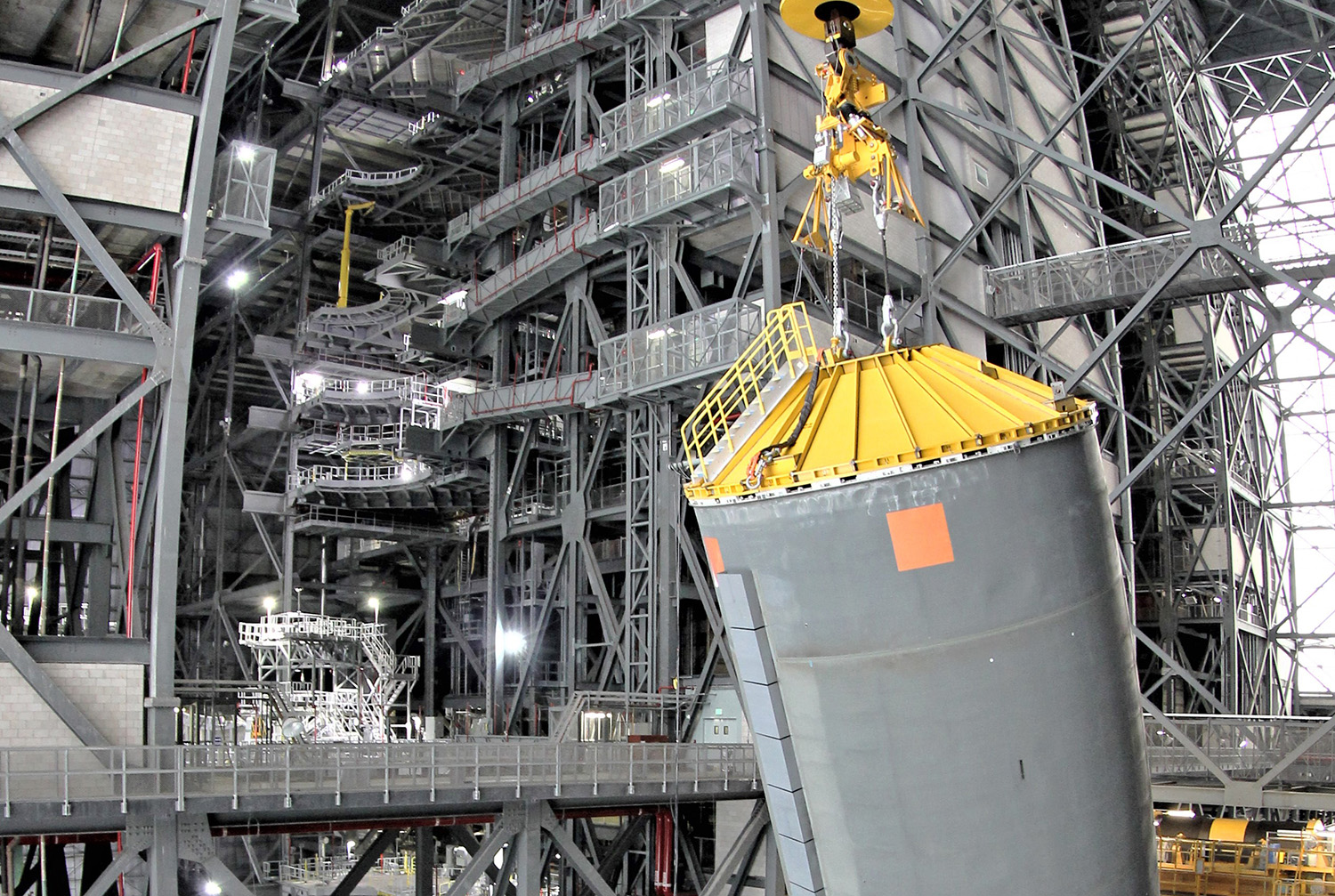

The team comprising engineers, technicians and workers from KSC Exploration Ground Systems (EGS) and contractor Jacobs spent last week rotating and lifting the mammoth pathfinder core stage replica from horizontal to vertical inside the cavernous VAB transfer aisle using a pair of overhead cranes working in tandem – and then hoisting it very carefully over the 192 foot level and then transferring it into High Bay 3.

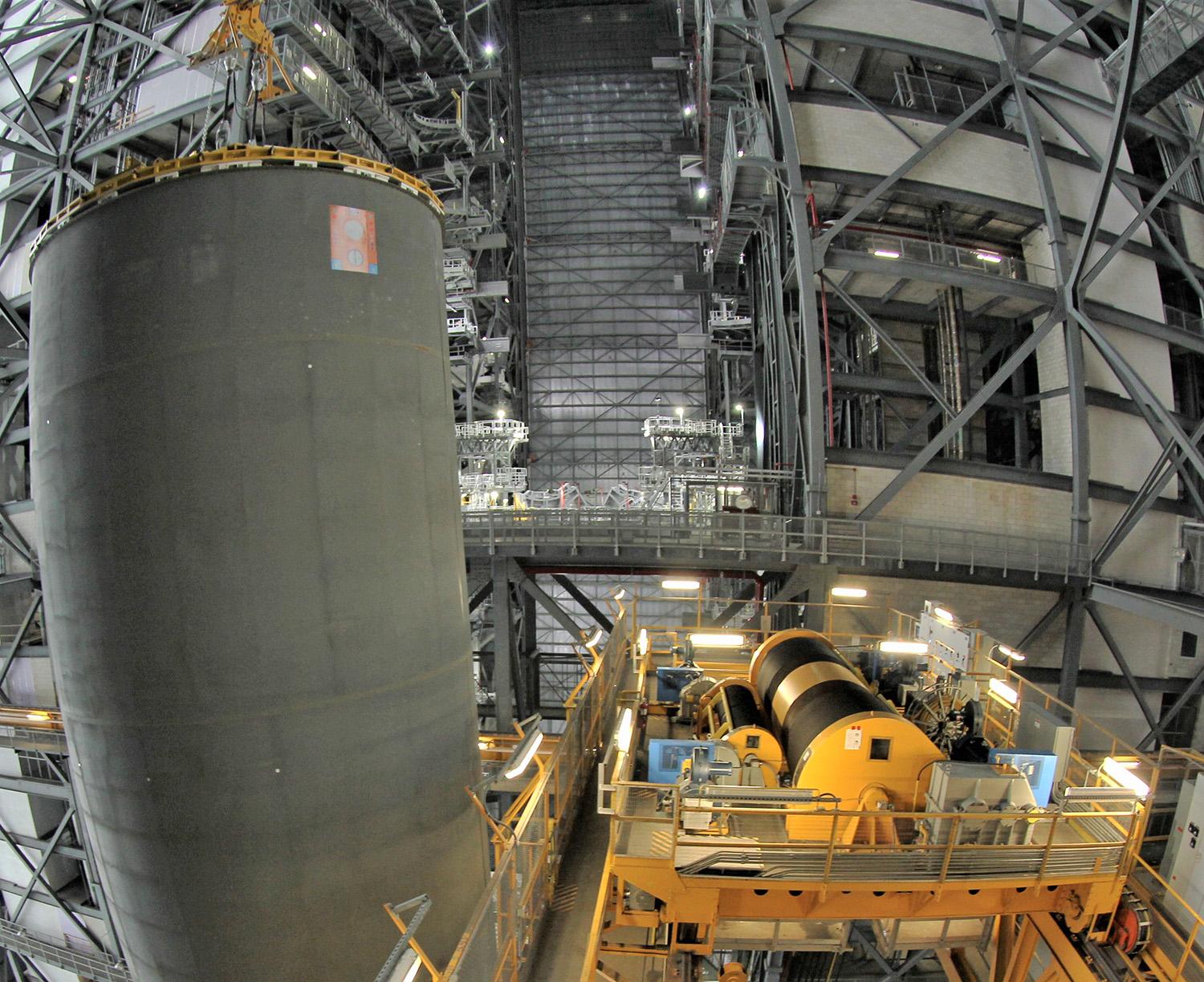

The next step was to lower the 21 story cylindrical test article down into High Bay 3 in between the fully extended platforms that provide worker access to the rocket at many levels for assembly of the SLS rocket for Artemis missions launching the Orion human deep space crew capsule to the Moon.

That entire dual crane lifting and placement procedure “where the team went up and over into High Bay 3, and down through the platforms in order to simulate the stacking operations was done on Oct. 16,” said Jim Bolton, EGS core stage element operations manager at Kennedy during an interview inside the VAB with Space UpClose on Oct. 17.

“We did that successfully on Oct 16 and that gives us a lot of confidence,” Bolton told me.

The media including Space UpClose were invited by NASA to observe one of the Pathfinder lifting operations inside the VAB on Thursday, Oct 17 from early morning to late afternoon.

Enjoy our UpClose photos from all around Pathfinder in the VAB at multiple levels and vantage points above, below, front and back – including from a fisheye ultra wide angle lens to capture the breadth of the building.

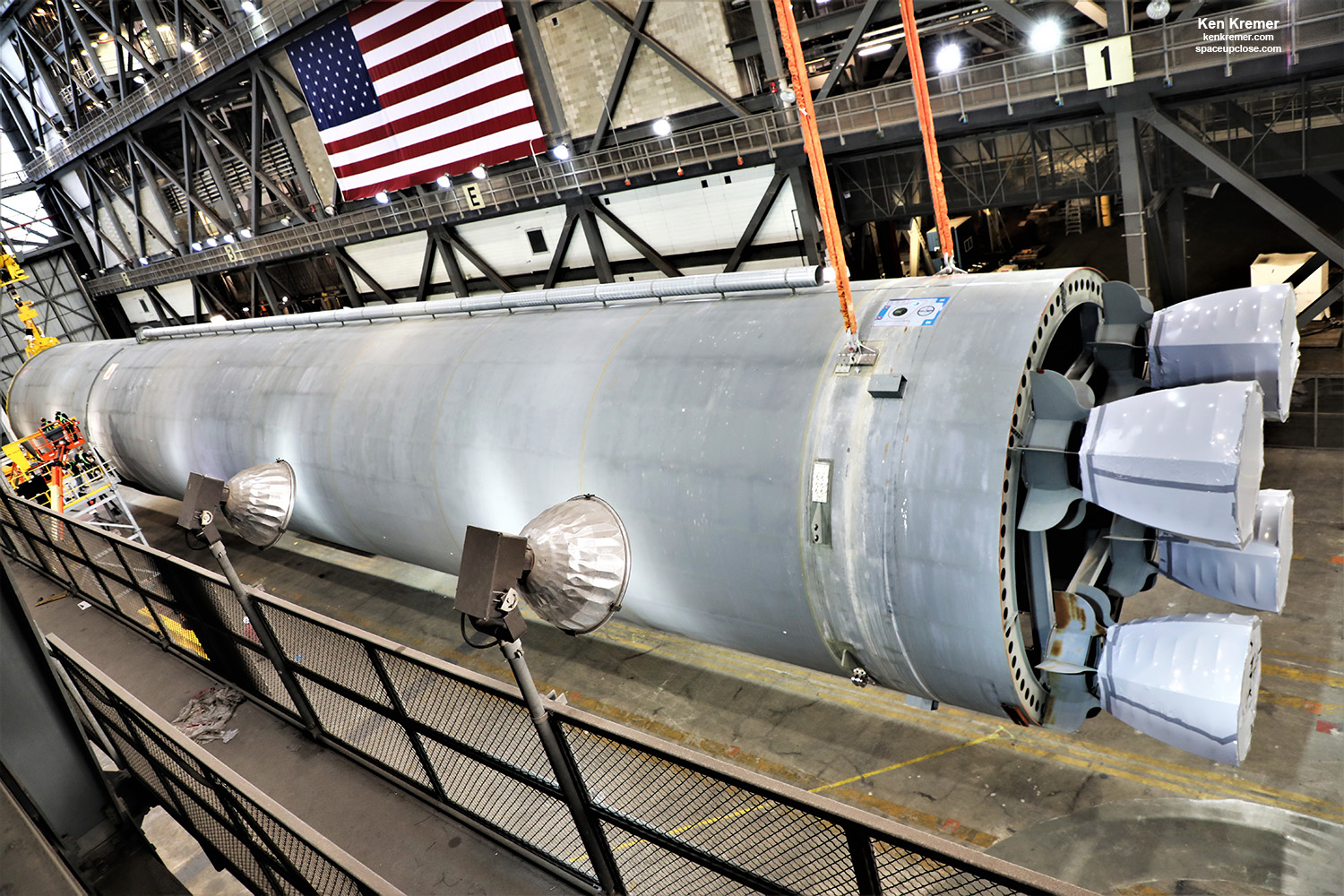

Pathfinder’s horizontal to vertical rotation lift took about 40 minutes altogether as the crew occasionally paused to ensure all was as it should be. And everything appeared to go just about perfectly well with no hiccups.

“The two cranes work in tandem rotating Pathfinder – one attached to lift the forward end and the other at the aft end, to raise the forward while bringing the aft closer to the forward,” Bolton explained.

“The aft 175 ton is then released and the 325 ton crane holds it vertical like a pencil.”

What were the lessons learned, I asked.

“There were many lessons learned, practicing all the procedures and going through all the steps and quality needs, practicing safe operations, executing the procedures, having our technicians read and run through all the steps and the operations to get the training required to be confident going into Artemis 1.”

“The key things were learned are practicing with the SLS provided ground support equipment, making sure we have confidence when we are transporting and operating when we are doing lifts, running the technicians stepwise through the operations, and meeting the requirements of the mission ahead.”

“More rotation lifting exercises are planned next week.”

Myself and several media colleagues witnessed the team practice offloading from the wheel lift transporters using both the 325 ton and 175 ton cranes, moving in the transfer aisle and finally a coordinated ballet of raising it to vertical position in front of High Bay 3 using all the specialized ground support equipment to train employees and certify all the equipment works properly.

Pegasus and Pathfinder sailed into and docked at the Turn Basin wharf by the world famous countdown clock at Kennedy nearly three weeks ago Friday afternoon, Sept. 27 after being towed by ocean-going and river-going tugboats for a nearly 1000-mile and week-long trek from NASA’s Stennis Space Center in Mississippi to KSC.

Technicians started offloading the 212-foot-long cylindrical Pathfinder from the 310-foot-long Pegasus barge the following Monday morning, Sept. 30 and then moved it a day later, Tuesday, Oct. 1 the short distance to the iconic Vehicle Assembly Building (VAB) for a month of maneuvering and stacking practice by NASA’s Exploration Ground Systems (EGS) team and contractor Jacobs before the first real SLS core stage arrives sometime in mid-2020 for eventual launch on the Artemis 1 mission in late 2020 or early 2021.

Check out our earlier eyewitness articles and photos of Pegasus KSC arrival and offloading.

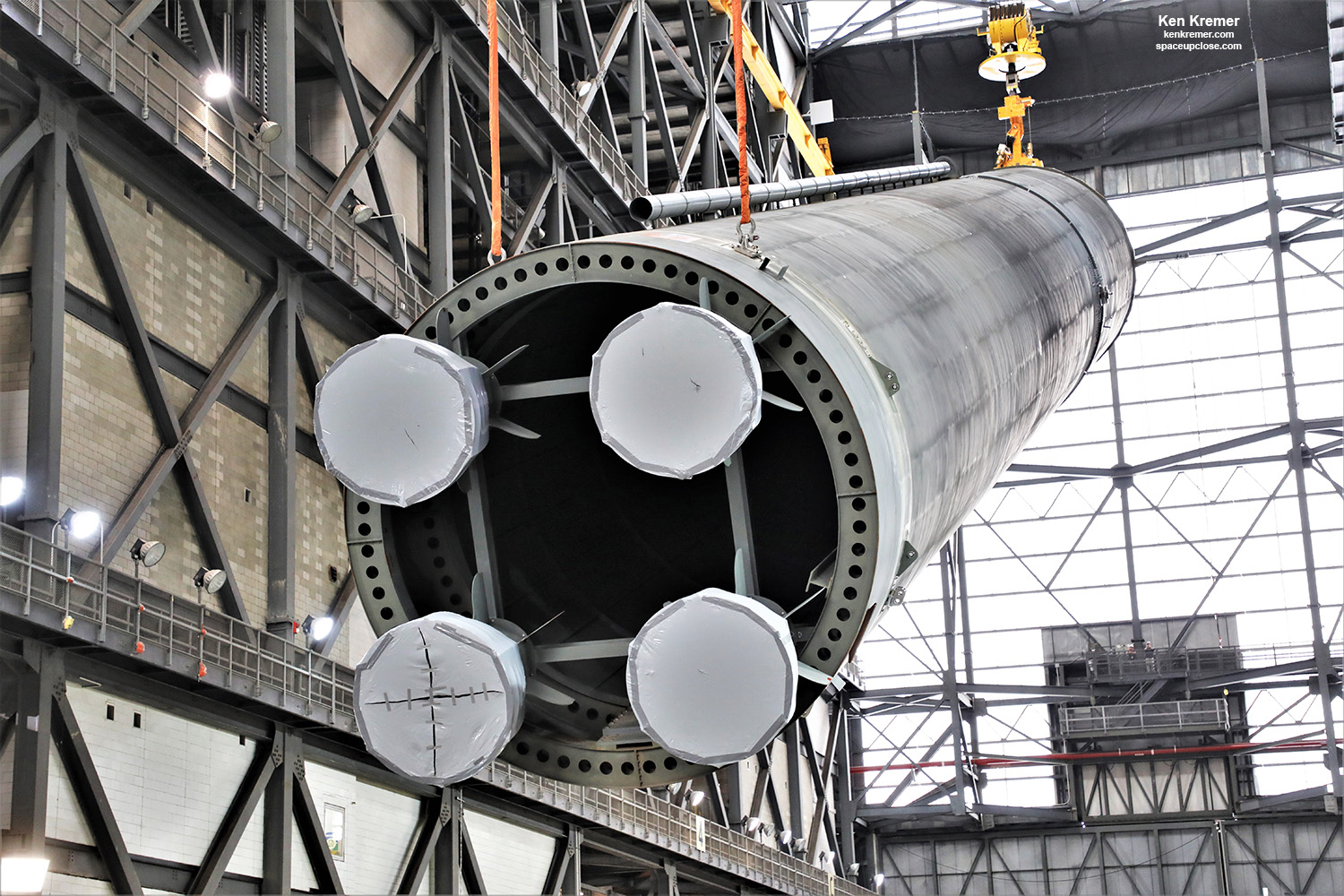

The 228,000 pound SLS core stage pathfinder is a full-scale mockup test article that is identical to the core stage in shape, size and weight. But the 27.6 foot diameter cylinder is hollow and lacking fuel tanks, built from stainless steel and has wire rim replica engine placeholders in place of the real RS-25 engines.

Nevertheless Pathfinder is gigantic and gives a clear vision of what’s in store with the gargantuan nature of SLS and is extremely helpful for training purposes now.

“This will help ensure that all core stage engineers and technicians are trained and certified in preparation for the flight core stage processing,” said Jim Bolton, EGS core stage element operations manager at Kennedy.

“It’s a very significant milestone that will demonstrate the capabilities and ability for KSC to receive, process and integrate that flight hardware.”

This month long work period is the only time Pathfinder will be present at KSC. The NASA EGS team told me it was always planned for Pathfinder to travel to KSC for these stacking exercises as part of preparations for launch of the Artemis 1 mission.

For this test phase the VAB crane crews lifted it vertically for placement into High Bay 3 – minus the Mobile Launcher which currently resides atop Launch Complex 39B at KSC. See our earlier articles and photos.

The lift and placement into High Bay 3 was run through completely one time – and was accomplished successfully on Oct. 16, Bolton told me. The rotation is being done several times and takes about 40 minutes.

“The pathfinder went up about 204 feet and over into High Bay 3, and down through the platforms in order to simulate the stacking operations and verify we have the clearances required for Artemis 1,” said Bolton in the VAB interview.

“The High Bay 3 installation work takes about an hour using the 325 ton overhead crane.”

“The reverse process to lift out and remove from High Bay 3 and place back on the ground takes about an hour and a half.”

“We did that successfully yesterday Oct 16. That gives us a lot of confidence. So we do not need to go back into High Bay 3 at this point.”

“We are on schedule to complete the practice and training exercises in the one month time period allotted.”

Crane crews lifted the long cylindrical test article off the transporter and raise it 200 feet into the vertical position using dual bridge cranes on the VAB roof.

The base of Pathfinder was hoisted up and over the 16th floor walkway, 196 feet high, in the VAB transfer aisle and then maneuver it sideways over to High Bay 3.

Then it was lowered by crane back down in between the two access platforms (F and K for the forward and aft SRB attach points) which were down and extended – with about 6 inches of clearance – and down to where the mobile launcher would normally reside.

About two dozen observers were watching all points as the pathfinder was lowered without incident.

Basically, this involves the same lifting and stacking procedures as were done for the Space Shuttle External Tank (ET).

Watch these two KSC videos showing the entire lift process:

Video Caption: 360 View of SLS Core Stage Pathfinder Lift, Camera 2: The Space Launch System’s Core Stage Pathfinder is lifted from the Vehicle Assembly Building’s transfer aisle and into High Bay 3 at NASA’s Kennedy Space Center on Oct. 16, 2019. The Pathfinder, or practice hardware, is being used by Exploration Ground Systems and its contractor, Jacobs, to practice offloading, moving, and stacking maneuvers, using important ground support equipment to train employees and certify all the equipment works properly. Credit: NASA/KSC

Video Caption: 360 View of SLS Core Stage Pathfinder Lift, Camera 1: Credit: NASA/KSC

The crane crew is highly experienced says NASA and is comprised largely of the same folks who worked on the shuttle ET – which was last launched in 2011.

But the crews haven’t done such a dual crane lifting operation since that final space shuttle mission STS-135 launched in July 2011.

However the SLS core stage is more than 50 feet longer then the ET.

NASA and Jacobs teams practiced the same stacking exercises on the pathfinder mock-up as if it were a real core stage.

The cranes are heritage from the space shuttle and Apollo eras.

“The 175 ton crane was refurbished since the shuttle time,’ Bolton told me. “It has been almost completely rebuilt with a high fidelity system. Its like a block upgrade.”

“The 325 ton crane is newer from the mid 1990s and has been upgraded incrementally.”

About 40 to 50 people are working on pathfinder operations during one 12 hour shift inside the VAB at any one time. For actual Artemis missions the team will run three shifts.

“The pathfinder, though not actual flight hardware, will provide the SLS program, Exploration Ground Systems (EGS) team with the opportunity to practice stacking maneuvers and certify the new system inside the Vehicle Assembly Building (VAB) High Bay 3 before Artemis flight hardware arrives next year,” say NASA officials.

“Pathfinder will be used to validate ground support equipment and demonstrate how the core stage will be integrated in the VAB – the same process the actual core stage will undergo when being processed for Artemis I.”

After the pathfinder exercises are completed soon it will be transported back onto the Pegasus barge and depart between Oct 31 to Nov. 2.

Pegasus is NASA’s one of a kind and football field sized barge used to transport the space vehicle hardware between NASA centers for testing and eventually to the launch site at the Kennedy Space Center in Florida.

The SLS core stage pathfinder was transported from NASA’s Stennis Space Center in Mississippi where it recently completed fit check testing for the upcoming ‘green run’ test of the first real SLS core stage for the Artemis 1 mission.

On Sept 27 Pegasus and Pathfinder arrived by way of Port Canaveral and the Banana River -accompanied by a KSC tracking ship and heading towards inland water ways to KSC Launch Complex 39 and the VAB. The inland path was dredged decades ago by NASA to open up access to the VAB at the KSC Turn Basin and Press site.

The 310 foot long Pegasus followed the same route used by NASA vessels decades earlier to ship Apollo moon rocket stages and Space Shuttle External tanks and solid rocket boosters.

NASA will conduct a full duration ‘green run’ engine fire test of the completed core stage at Stennis to fully confirm its readiness for flight on Artemis 1. But that test will require six months of intense work by NASA and contractor teams.

Meanwhile the Orion Artemis 1 crew capsule is nearing completion nearby in the Operations and Checkout building I recently visited at KSC.

Watch for our upcoming Orion update.

Stay tuned here for Ken’s continuing Earth and Planetary science and human spaceflight news: www.kenkremer.com –www.spaceupclose.com – twitter @ken_kremer – email: ken at kenkremer.com